Matthew Fickett

Architect

Matthew Fickett AIA, CPHC, LEED

I lead teams of talented architects and engineers to create high performance research space. My specialty is working directly with scientists to create environments which support the physical and process requirements of their work; I especially welcome opportunities to create unique, specialty labs for novel research. My designs come from a physics-based understanding of requirements (scientific needs and sustainability) and an emphasis on the human experience.

matthew.fickett@gmail.com | (617) 645 5324 | Boston, Massachusetts | matthewfickett.com

You are seeing a degraded version of this page because you are using Internet Explorer. Please use a modern browser like Chrome, Safari, or Edge.

HDR

2023 - currentManaging Principal, Boston Architecture

SGA

2021 - 2022Principal, Science and Technology

I created lab design standards and tools for our studio, including a library of Revit content, lab planning tools, and marketing material. I also mentored staff in lab design, led selected projects, and participated in firmwide business developement.

EYP

2019 - 2021Senior Lab Planner, Senior Associate

- Johns Hopkins University Materials Characterization and Processing (MCP) Facility

Project Architect for 20,000 SF facility housing ten high-end instrument suites and supporting labs - University of New Mexico Electron microscope suite

Project Architect for TEM suite in sub-grade level of existing building

Perkins+Will

2016 - 2019Project Architect, Associate

- Fermilab IERC

Architectural lead for particle physics detector research and construction laboratory and ISO 6 cleanroom spaces, programming through final design - Confidential Medical device cleanrooms

Project Architect for manufacturing cleanroom expansion and modernization, temporary cleanroom, and pilot manufacturing line cleanroom; all ISO 6 - Columbia Electron microscope suite

Project Architect and Project Manager, for cryo-EM suite in sub-grade level of existing building adjacent to elevated railway and active MRI suites - Keralink Cornea processing facility

Project Architect, Project Manager, production lead, and photographer for office, wet lab, and ISO 6 cleanroom lab - MIT Lincoln Lab Chip on Board Lab

Project Architect and production lead for micron-level clean-not-classified electronics assembly and testing lab adjacent to active loading dock - University of Kansas ISB

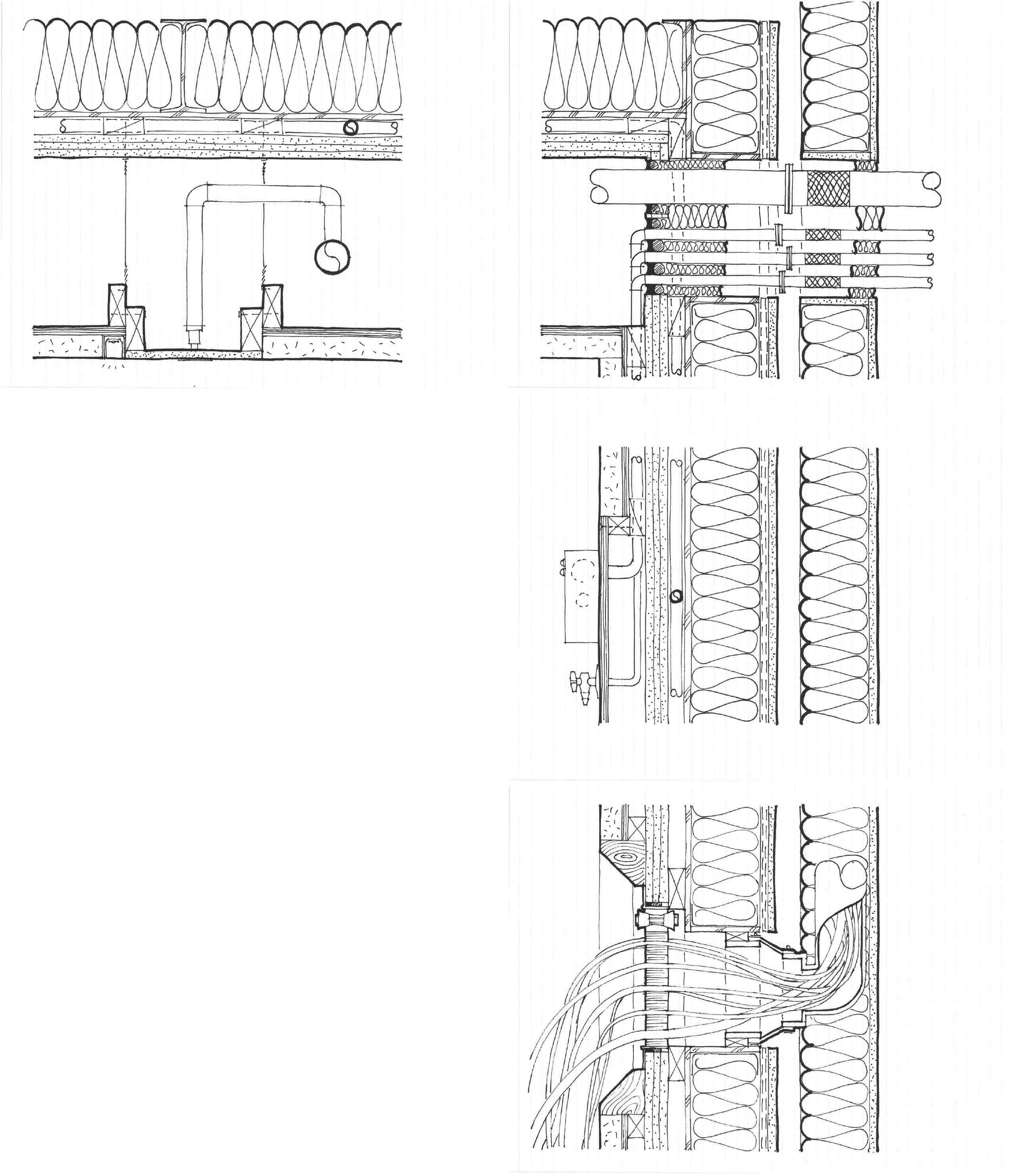

Architectural lead and production lead for suite of four electron imaging instruments and multiple low-vibration laser- and quantum-materials laboratories - Explanatory Drawings Nano Cleanroom; Electron Imaging

Layout, production, and writing of explanatory cut-away posters

Payette

2013 - 2016Architect

- Skolkovo University Core cleanroom and imaging facilities; Center for Quantum Materials

Architectural lead and production lead for ISO 4 - 6 nanotech semiconductor research and fabrication cleanroom, and labs for Quantum Materials department - Mass DOER Net Zero Energy Building Research

Validating and calibrating building energy models against field measurements and operational data to support MASS DOER grant work by Payette's Building Science group - MGH Suites for Interventional Radiology, X-Ray, and Emergency Department MRI

Coordination and production for a series of high-performance imaging and radiology suites in operational areas of Massachusetts General Hospital

Wilson Architects

2012 - 2013Architect

- MIT MIT.nano (formerly nMaSS), cleanroom and electron imaging suites

- Vanderbilt TEAM building, cleanroom and electron imaging suites

For both projects: architectural and production lead for ISO 4 - 6 nanotech semiconductor research and fabrication cleanrooms, and suites of electron imaging instruments

Payette

2006-2012Designer

- GWU School of Public Health, auditoria and monumental stairs

Coordination and documentation of three main auditoria, including parametrically-designed acoustic paneling, and atrium's monumental stairs - Harvard Sherman Fairchild Laboratory, zebrafish facility

Architectural and production lead, and photographer, for zebrafish facility in lowest level of Sherman Fairchild laboratory - UMass Medical Center Ambulatory Care Center, nuclear medicine and cardiac medicine floors

Architectural lead and production lead for two floors of outpatient care facilities, including nuclear medicine imaging suite, from programming through construction

Rensselaer Polytechnic Institute

2001-2006Five-year Bachelor's of Architecture

Minor in Organizational Psychology

magna cum laude

Keralink

This wet lab and ISO 6 cleanroom facility for a cornea-transplant non-profit replaced an existing office fitout. To reduce costs and increase transparency, the lab is designed to re-use existing glass office partitions.Role: Project Manager, Project Architect, and production of most documentation. At Perkins+Will.

Image: Standing near the entrance, looking into the clean-not-classified wet lab area, with the cleanroom (blue wall) beyond.

(Photo: Matthew Fickett)

Columbia Electron Microscope Suite

Researchers at Columbia University won a Nobel prize for invention of a new technique for electron microscopy at cryogenic temperatures. The program for this project was to locate one of these new instruments in the basement of an existing building.As the site was adjacent to an active subway line (on one side) and an active MRI suite (on the other side), considerable shielding and isolation against vibration, acoustic noise, and magnetic fields was required. The primary design challenge was to accomplish this isolation while providing the services, and exacting environmental control, required by the instrument.

Role: Project Manager and Project Architect. At Perkins+Will.

Image: Concept sketch for isolation details and wall section at shielded instrument room.

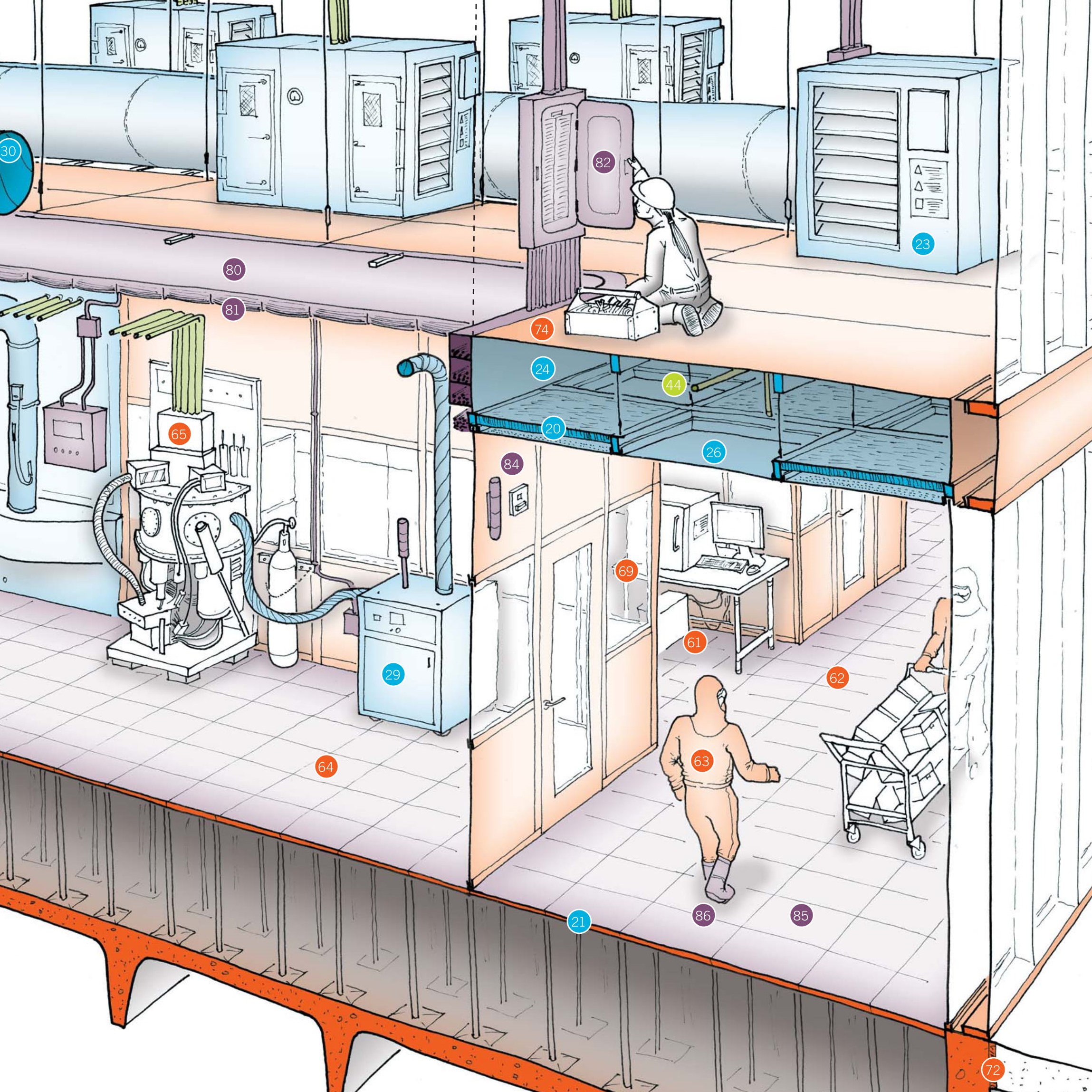

Explanatory Drawings

I wrote and illustrated explanatory drawings for technical project types I work on. I use these internally, to explain the highly technical facilities I design to team members working on the same project, and externally, to illustrate design principles for these project types when I am teaching or speaking publicly.Download these at full size (30x42) here:

Role: Concept and execution of complete project. At Perkins+Will.

Image: Detail from Nano Cleanroom drawing.

Harvard

Sherman Fairchild Zebrafish FacilityAs part of the Sherman Fairchild lab renovation, I led the design of a new zebrafish facility in the basement. The existing structure clears the ceiling by as little as four inches in some locations; the systems coordination to achieve an environment both functional and asthetically pleasing was significant. The facility was designed for future installation of feeding robots, requiring the installation of concealed supporting steel above each row of tanks.

Role: Design, documentation, and coordination of this facility within the scope of a whole-building renovation. At Payette.

Image: The main aisle looking toward the zebrafish water pump room.

(Photo: Matthew Fickett)

Credentials

CPHC (since 2017), Certified Passive House Consultant

LEED AP (since 2008), Version 2 of LEED

Speaking

- Helium: Facility and engineering systems for recovering spent gas, reducing demand and costs

- Applying the rigorous Passive House energy efficiency standard to lab space (with Julie Janiski, Buro Happold)

Tradeline College and University Science and Engineering Facilities 2017

- Facility plans for advanced imaging: Critical details for success

- Cleanrooms: Requirements, support services, and impacts on building design

Aquaculture America 2012

- Architectural design and construction of a new zebrafish research facility in an existing laboratory building

Writing

- What's a cleanroom and how do I make one? (Payette)

- A Cleanroom in Two Images (Payette)

- How to Skin a Cleanroom (Payette)

- Choosing the Right Clean Class and Saving Money (EYP)

Laboratory Buildings

- All-Electric Laboratory Buildings: Why and How (EYP)

- Net Zero Laboratory Buildings Part 1: Understanding Net Zero (SGA)

- Net Zero Laboratory Buildings Part 2: Space Conditioning and Fume Hoods (SGA)

- Net Zero Laboratory Buildings Part 3: Building Infrastructure, Cost, and Emergency Power (SGA)

- 2CFM/SF Is Wrong | Part 1: Lab Ventilation Basics (SGA)

- 2CFM/SF Is Wrong | Part 2: What About Fume Hoods? (SGA)

- 2CFM/SF Is Wrong | Part 3: Vivariums And Other Details (SGA)

Architectural Practice

- Where Revit Meets Hand Drawing (Payette)

- Color Universal Design and Architecture (Payette)

Teaching

- Comprehensive Design Studio (professor David Fannon): critic for all reviews throughout the studio, 2014 - 2020

Columbia University

- Core 2 Studio (professor Christoph Kumpusch): critic for intermediate and final reviews, 2018

Boston Architectural College

- A-2 Studio: co-led with Becky Zollin, 2007

- A-1 Studio (professor Becky Zollin): critic for intermediate and final reviews, 2007